Importance of micromeritics in pharmacy terms of use template

The field of pharmacy is constantly evolving, with new medications and therapies being developed every day. One crucial aspect of the pharmacy industry is the development and production of pharmaceutical powders and particles. The science of micromeritics plays a significant role in ensuring the quality and efficacy of these powders and particles.

Micromeritics is the study of the physical and chemical properties of particles and their behavior in different environments. It involves the analysis of particle size, shape, surface area, and porosity, among other parameters. In the context of pharmacy, micromeritics is essential in the formulation and manufacturing of drugs, as it influences the drug's dissolution rate, bioavailability, and stability.

Pharmacy terms of use templates include specific guidelines and regulations that pharmaceutical companies must adhere to when it comes to the development and production of drugs. Micromeritics is often mentioned in these templates as it sets standards for the particle size distribution and other parameters that impact the drug's performance.

By incorporating micromeritics into pharmacy terms of use templates, pharmaceutical companies ensure that their products meet the required quality standards and are safe and effective for patients. The guidelines outlined in these templates help regulate and standardize the production processes, thereby minimizing variations and inconsistencies in drug performance.

The Importance of Micromeritics in Pharmacy Industry

Micromeritics is a field of science that plays a crucial role in the pharmacy industry. It focuses on the physical characterization of particles and the study of their behavior, which is essential for the formulation and development of pharmaceutical products.

Understanding the properties of particles is vital in pharmacy as it directly affects the drug's efficacy, stability, and bioavailability. Micromeritics helps in determining the particle size, shape, surface area, and porosity, which influence the drug's dissolution rate, absorption, and release profile.

Particle size is a critical parameter in pharmaceutical formulation as it affects the dosage form's performance. Micromeritics techniques, such as laser diffraction and microscopy, are used to measure and analyze particle size distribution, enabling pharmaceutical scientists to optimize drug delivery systems and ensure consistent drug release.

Particle shape also plays a significant role in drug performance. Micromeritics techniques, such as image analysis, help identify particle shape characteristics such as aspect ratio and sphericity. This knowledge assists in designing dosage forms that improve drug stability and minimize particle aggregation.

Surface area measurement is crucial in the evaluation of drug powders and their interaction with excipients. Micromeritics techniques like the BET method enable the determination of specific surface area, providing insights into drug-excipient compatibility, surface chemistry, and potential drug degradation pathways.

Porosity analysis is essential in understanding the drug release mechanism from solid dosage forms. Micromeritics techniques, like mercury intrusion porosimetry, help in determining the pore size distribution and pore volume, which aid in optimizing drug release rates and controlling the release kinetics.

In conclusion, micromeritics plays a vital role in the pharmacy industry by providing valuable insights into the physical properties of drug particles. These insights help in formulating stable and effective dosage forms, ensuring optimal drug delivery and patient outcomes.

Understanding Micromeritics: Definition, Principles, and Applications

In the field of pharmacy, micromeritics plays a significant role in understanding the physical properties of pharmaceutical materials at the microscopic level. Micromeritics involves the study of particles, their size distribution, surface area, and porosity, which are all important factors in drug formulation and manufacturing processes.

Definition

Micromeritics refers to the science and technology of small particles and their interactions. It encompasses the measurement, characterization, and understanding of particle size, shape, surface area, and porosity. By studying these properties, scientists can gain insights into the behavior and performance of pharmaceutical materials.

Principles

The principles of micromeritics revolve around the understanding of how particles behave and interact at the microscale. It involves various techniques and methodologies to measure particle size, such as laser diffraction, sedimentation, and microscopy. Surface area and porosity measurements provide insights into the interparticle contact and drug loading capacity of materials.

Additionally, the study of particle shape helps in understanding the flowability and compactability of pharmaceutical powders, which is crucial for tablet manufacturing. The principles of micromeritics provide a foundation for optimizing drug formulation, ensuring product quality, and enhancing drug delivery efficiency.

Applications

Micromeritics has diverse applications within the field of pharmacy. It is used to determine the optimal particle size for drug delivery systems such as nanoparticles and microparticles. By controlling the particle size, drug release kinetics and bioavailability can be improved.

Furthermore, micromeritic characterization is essential for understanding the physical stability and formulation parameters of solid dosage forms. It helps in identifying the ideal excipients, determining the flow properties of granules, and predicting the compressibility of powders for tablet production.

Micromeritics also finds use in quality control and product development processes for pharmaceutical companies. By accurately measuring particle size, surface area, and porosity, manufacturers can ensure consistency in drug performance and enhance the reproducibility of their products.

Micromeritic Techniques: Tools and Methods for Particle Size Analysis

Introduction

Particle size analysis is a critical aspect of pharmaceutical research and development, as it affects the performance and efficacy of drug products. Micromeritic techniques provide valuable tools and methods for measuring and analyzing the particle size of pharmaceutical powders and solid dosage forms. These techniques help researchers and scientists understand the physical properties and behavior of particles, enabling them to optimize drug formulation and manufacturing processes.

Laser Diffraction

One commonly used micromeritic technique for particle size analysis is laser diffraction. This method involves passing a laser beam through a sample and measuring the angles and intensities of the scattered light. By analyzing the scattering pattern, the particle size distribution can be determined. Laser diffraction is non-destructive, fast, and suitable for a wide range of particle sizes, making it a versatile tool in pharmaceutical research.

Image Analysis

Another important micromeritic technique for particle size analysis is image analysis. This method involves capturing images of particles and using software to measure their sizes and shapes. Image analysis can provide valuable information about particle morphology, such as roundness, aspect ratio, and surface roughness. It is particularly useful for analyzing irregularly shaped particles found in pharmaceutical powders.

Sieving

Sieving is a traditional and widely used technique for particle size analysis in pharmacy. This method involves passing particles through a series of stacked sieves with different mesh sizes. The particles are separated by size, and the percentage of particles retained on each sieve is determined. Sieving is simple, cost-effective, and suitable for large-scale analysis. However, it is limited to particles larger than the mesh size of the smallest sieve used.

Other Techniques

In addition to laser diffraction, image analysis, and sieving, there are other micromeritic techniques used in particle size analysis, such as sedimentation, electron microscopy, and light microscopy. Each technique has its advantages and limitations, and the choice of method depends on the specific requirements of the pharmaceutical application.

Conclusion

Micromeritic techniques play a crucial role in particle size analysis for pharmaceutical research and development. The tools and methods discussed above, including laser diffraction, image analysis, and sieving, provide valuable insights into the physical properties and behavior of particles. By accurately measuring and understanding particle size distribution, researchers and scientists can optimize drug formulation, manufacturing processes, and ensure the quality and performance of pharmaceutical products.

Role of Micromeritics in Pharmacy Formulation Development

Micromeritics plays a crucial role in the development of pharmaceutical formulations. It involves the study of small particles and their characteristics, which are of utmost importance in the pharmacy industry.

Particle size distribution: Micromeritics helps in determining the particle size distribution of the active pharmaceutical ingredients (APIs) used in the formulation. This information is vital as it affects the drug's solubility, dissolution rate, and bioavailability. Different particle sizes can also impact the stability and flow properties of the final product.

Powder flow properties: The flow properties of powders are critical in the manufacturing process. Micromeritics helps in evaluating various parameters such as angle of repose, bulk density, and compressibility index, which determine the flow characteristics of the powder. This information helps in designing suitable formulation processes and ensures consistent quality and efficacy of the final product.

Surface area analysis: Micromeritics helps in determining the specific surface area of the particles. This information is crucial in understanding the drug's dissolution behavior, as higher surface area can lead to faster dissolution and absorption. Surface area analysis is also important in assessing the drug's compatibility with excipients and in designing optimal dosage forms.

Pore size and porosity: Micromeritics allows the measurement of pore size and porosity of pharmaceutical powders. This information is valuable in selecting appropriate excipients, as well as understanding the drug release mechanism from different formulations. Pore size and porosity can affect the drug's stability, release rate, and final product performance.

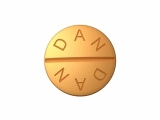

Uniformity of dosage forms: Micromeritics plays a vital role in ensuring the uniformity of pharmaceutical dosage forms, such as tablets and capsules. It helps in evaluating parameters like particle size, density, and compressibility, which directly impact the quality and consistency of the final product. Uniformity in dosage forms is crucial for accurate drug dosing and patient safety.

In summary, micromeritics is an essential tool in pharmacy formulation development. It provides valuable insights into particle characteristics, powder flow properties, surface area, pore size, and uniformity of dosage forms. Utilizing micromeritics helps in optimizing pharmaceutical formulations, ensuring product quality, and enhancing patient outcomes.

Quality Control and Assurance: Micromeritics in Pharmaceutical Manufacturing

In the field of pharmaceutical manufacturing, quality control and assurance play a crucial role in ensuring the safety and efficacy of drugs. One important aspect of quality control is micromeritics, which involves the measurement and characterization of particles and powders.

Micromeritics is essential to the pharmaceutical industry as it helps in determining various properties of drug substances and excipients, such as particle size, shape, surface area, and porosity. These properties can have a significant impact on the performance and stability of a drug formulation.

By understanding the micromeritics of pharmaceutical ingredients, manufacturers can optimize the formulation process and ensure consistency in the final product. For example, the particle size and shape of a drug substance can affect its dissolution rate, bioavailability, and stability. By carefully selecting and controlling these properties, manufacturers can enhance the effectiveness and safety of the drug.

In addition, micromeritics plays a crucial role in the development and evaluation of drug delivery systems. For instance, in the case of inhalation therapies, the particle size and surface area of the drug particles can influence their deposition in the lungs and ultimately determine the therapeutic efficacy. Micromeritics can help in designing and optimizing drug delivery systems to achieve the desired therapeutic outcomes.

Micromeritics is also valuable in quality assurance processes throughout pharmaceutical manufacturing. By using specialized instruments and techniques, manufacturers can monitor and control the particle properties of raw materials, intermediates, and finished products, ensuring consistency and compliance with regulatory standards.

In conclusion, micromeritics is an essential tool in quality control and assurance in pharmaceutical manufacturing. It provides valuable insights into the properties of drug substances and excipients, facilitates formulation optimization and drug delivery system development, and ensures consistency and compliance throughout the manufacturing process.

Implications of Micromeritics on Drug Delivery Systems and Bioavailability

1. Particle Size Distribution:

The particle size distribution plays a crucial role in the development of drug delivery systems and the bioavailability of pharmaceutical drugs. By understanding the micromeritics of particle size distribution, researchers can design drug delivery systems that optimize drug release and absorption.

For example, nanoparticles with a controlled size distribution can enhance drug solubility, increase drug loading capacity, and improve drug stability. This allows for better delivery of the drug to the target site, increasing its bioavailability and therapeutic efficacy.

2. Surface Area and Porosity:

The surface area and porosity of drug particles also impact drug delivery systems and bioavailability. A higher surface area to volume ratio leads to increased drug dissolution and absorption rates.

Nanoparticles with a high surface area and porosity can provide a larger area for drug molecules to interact with the surrounding environment, leading to improved drug release and absorption. Moreover, the porosity of nanoparticles can be tailored to control the drug release rate, resulting in sustained and controlled drug delivery.

3. Polymorphism and Crystallinity:

Micromeritics also influences the polymorphism and crystallinity of drug particles, which can affect drug delivery systems and bioavailability. Polymorphism refers to the ability of a substance to exist in different crystal structures with unique properties.

By understanding the micromeritics of polymorphism, pharmaceutical researchers can select the most stable and bioavailable crystal form of a drug. This can impact the dissolution rate, solubility, and bioavailability of the drug, ultimately influencing its therapeutic efficacy.

4. Flowability and Compression Characteristics:

The flowability and compression characteristics of drug particles are essential considerations in the development of solid dosage forms such as tablets and capsules. These characteristics determine the manufacturability and performance of the drug delivery system.

Understanding the micromeritics of flowability and compression allows for the optimization of tablet formulations, ensuring uniform drug content and consistent release profiles. This is crucial for achieving reproducible drug release and maintaining therapeutic efficacy.

In conclusion, micromeritics has significant implications on drug delivery systems and bioavailability. By understanding and controlling particle size distribution, surface area and porosity, polymorphism and crystallinity, as well as flowability and compression characteristics, pharmaceutical researchers can develop effective drug formulations that enhance drug release, absorption, and therapeutic outcomes.

Follow us on Twitter @Pharmaceuticals #Pharmacy

Subscribe on YouTube @PharmaceuticalsYouTube

Be the first to comment on "Importance of micromeritics in pharmacy terms of use template"